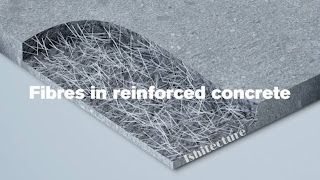

In this world of daily new inventions, we discover new

materials very often. One such material is FRC (Fibre-Reinforced Concrete), it

contains fibrous materials (short discrete fibres uniformly distributed and

randomly oriented) which increases structural integrity.

Use of fibre for reinforcement has been continued since

Mesopotamian civilization, they used the straw to strengthen sun-baked bricks.

Horsehair was employed in mortar and straw in mud bricks. Asbestos fibres were

used in concrete in 1900. Researches continue even today to enhance the

standard of concrete and different types of fibres like steel fibres, glass

fibres, synthetic fibre (polypropylene and nylon fibres) and natural fibres

(coir and hay).

Fibres may be circular or flat. Continuous meshes, woven

fabrics and long wires or rods are not discrete fibres. FRC can be used

on-ground floors, pavements and might be deemed for construction parts alone or

hand-tied like beams, pliers, foundations, etc. It is more cost-effective than

hand-tied rebar and increases tensile strength many times.

The amount of fibres added is measured in percentage of the

entire volume of the composite which ranges from 0.1-3%. The aspect ratio of

the fibre is the ratio of length and diameter which is often from 30-150. The

shape, dimension and length of fibre are important. If the length is simply too

long, the fibre tends to ball and creates workability problems. If the modulus

of elasticity of the fibre is higher than the matrix (concrete or mortar

binder) then it helps to hold the load by increasing tensile strength.

An example can be of short hair-shaped glass fibre, which is

effective the first few hours after pouring the concrete and reduces cracking

while the concrete is stiffening but there is no increase in concrete tensile

strength.

EFFECTS OF FIBERS

Fibres control the plastic shrinkage and drying shrinkage in

concrete. It reduces permeability thus reducing bleeding of water. Some types

of fibres produce greater impact, abrasion and shatter resistance. But the

fibres don’t increase flexural strength so it cannot replace moment resisting

or structural steel reinforcement.

NECESSITY OF FIBRES

The fibres increase the tensile strength of concrete and

reduce air and water voids. It increases the durability of concrete.

Orientation and volume of fibres have a big influence on the creep performance

of rebars. Graphite and glass have excellent resistance to creep. Add small,

closely spaced and uniformly dispersed fibres to concrete for crack resistance.

Many new types of research are being carried out to develop

better materials. An FRC sub-category named High-Performance Fibre

Reinforcement Concrete (HPFRC) claims more resistance to cracking and is

lighter than traditional concrete. More studies are being conducted to induce

better material than we have got today, and who knows if the long run holds

some advanced materials which can take building construction to a brand new

level.

Well explained concrete materials

ReplyDelete